Improving Workplace Safety in Chile through Proactive Inspections

Every year, thousands of Chileans are killed or injured in work-related accidents. This was recently brought to light during the 2010 Copiapó mining accident. Chile’s labor ministry, Dirección del Trabajo (DT), is tasked with increasing workplace safety through inspections and enforcement. But DT’s inspections are largely reactive: complaints come in and then an inspection is completed, often after an injury or death. Preventative inspections can help find safety issues before bad things happen.

DT has started moving to preventative inspections. They hired data scientists, built some models, and even ran field trials. But their efforts ran into many challenges, ranging from having data on what labor facilities even exist to identifying new facilities that might be at risk of violating workplace safety. Tax records report the location of the company’s headquarters, but the government may not know where other corporate facilities exist. DT’s inspectors wasted a lot of time going to non-existent facilities (the facility had closed or moved). Inspectors are assigned to regions and sometimes to industries and violation types. The inspection list is generated once a month, but DT doesn’t collect all of the labels until after another list is produced. Only a small portion of facilities are ever inspected —we don’t know if a violation existed unless inspectors went there.

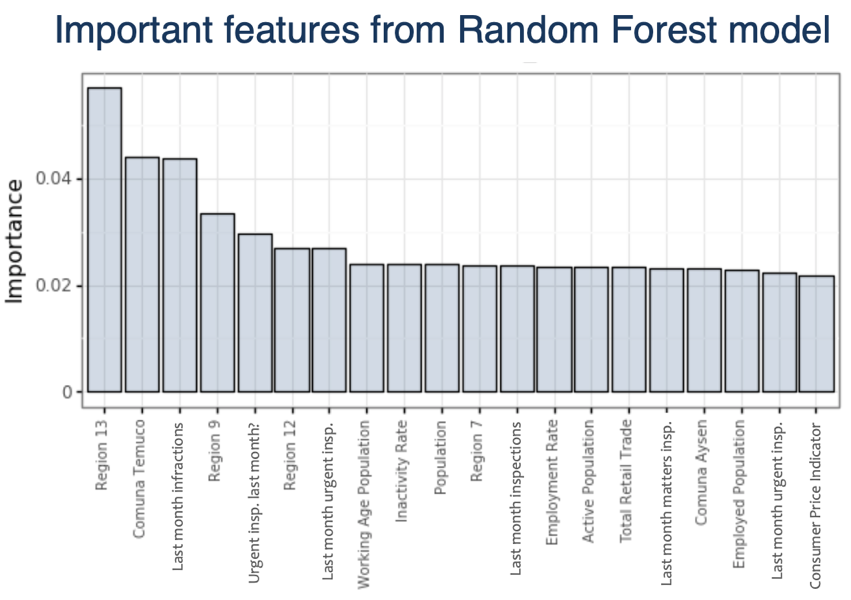

This summer, DT partnered with DSSG to help address such data science problems. Fellows Ancil Crayton, Sonia Mendizabal, Emma Remy, and Surabhi Trivedi, along with Technical Mentor Joe Walsh and Project Manager Mirian Lima, worked with DT to build more accurate and useful machine learning models to help DT perform preventative inspections. DT provided DSSG with data from the last 10 years of inspections including employee numbers and extensive company and facility specifications. DSSG also obtained copper prices from the Commodity Exchange and other macroeconomic data from The Organisation for Economic Co-operation and Development.

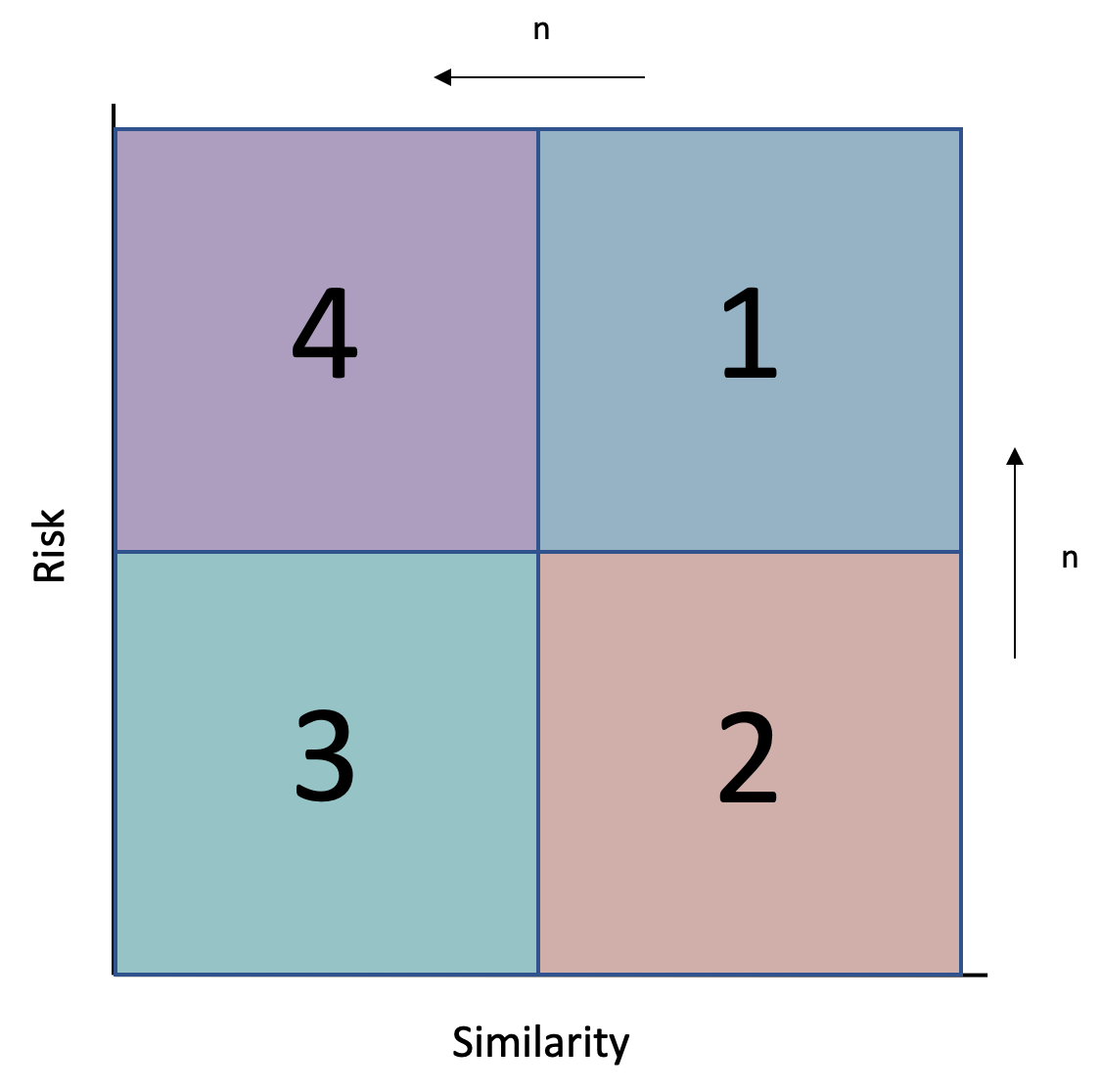

DSSG built a model to assess whether a facility would be found to have a violation if inspected. In addition, we also built a “similarity” model, assessing how similar a facility is to those previously inspected. Fewer than half of facilities have been inspected in the past, and they differ in significant ways from the rest, not the least of which is that they haven’t had safety complaints. By plotting risk score against similarity, DT can easily compare a facility’s risk and our confidence in the score. The higher the facility, the higher the estimated risk; and the farther right the facility, the more the facility is like other facilities that have been inspected. DT will want to inspect facilities from all four quadrants, but more from 1 and 4 than 3 and 2, and more from 4 and 3 than 1 and 2.

DT employs a limited number of inspectors and more often than not they inspect facilities with no hazards. Their capacity allows them to inspect about 20% of the companies located in Chile. Their hope is to identify and inspect the most likely offenders and also create a culture of anticipating inspection. By accomplishing these goals, DT can ensure workplaces in Chile become more compliant with labor laws leading to a safer and better environment for workers.

Bias detection: violation and inspection model

This project was transitioned to DSaPP (Center for Data Science and Public Policy at the University of Chicago) for improving the machine learning models and designing and conducting field trials. The trials will use both a list of facilities produced by the model and a random sampling stratified by region and industry to:

- Test the accuracy of the existing model and its predicted risk scores

- Calculate a base rate and identify existing biases in the inspection process

We expect our work to effect a reduction in inspection bias by efficiently using results from the inspection model and incorporating geographical and industry constraints in predicting risk. Future work to ensure safety in Chile’s workplaces includes:

- Developing a user-friendly interface integrating our model with DT’s existing systems

- Providing DT with motivation and tools to develop further data science-supported projects

The project also serves as a capacity-building opportunity for DT, with the goal of incorporating data science methods across Chilean public services.